Features

01

Advanced Technological Capabilities

02

Expertise and Experience

03

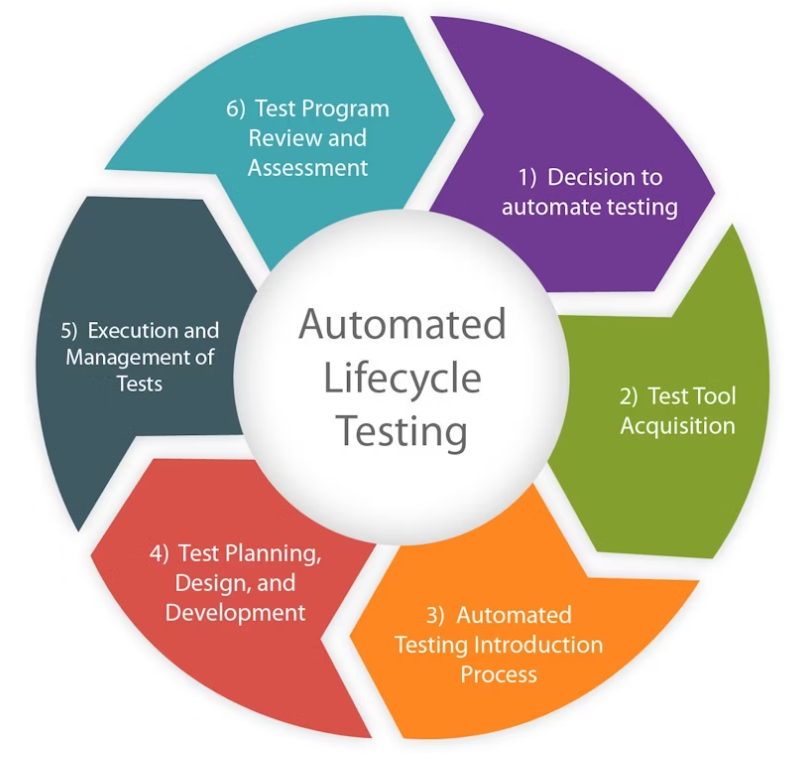

Attention to Detail and Quality Assurance

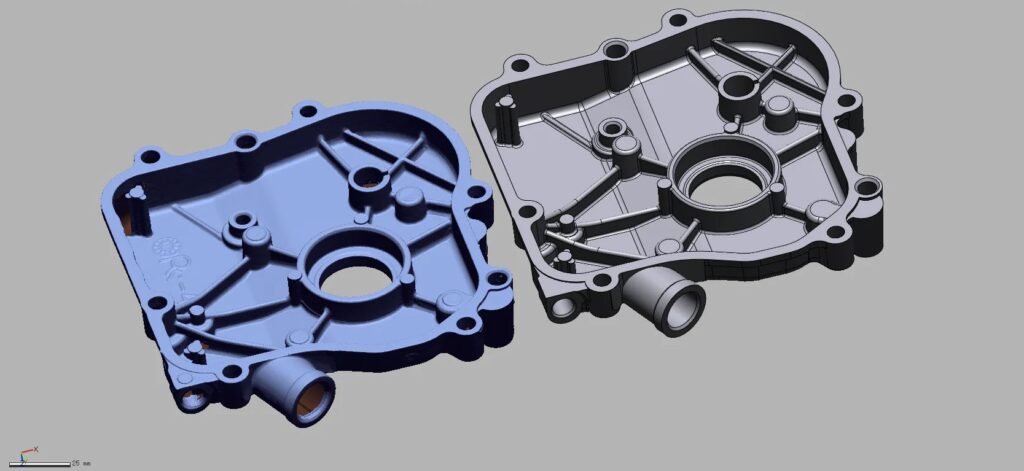

Reverse Engineering Services

Explore the range of services.

01

Laser 3D Scanning

Precision Scanning for Accurate Measurements. Our Laser 3D Scanning service utilizes infrared-based laser technology to provide precise and accurate 3D measurements of your parts. Obtain highly accurate dimensional data for complex geometries, ensuring exact measurements and reducing errors in the manufacturing process.

02

Visual 3D Scanning (Image-Based)

High-Resolution Visual Capture for Precision Modeling. Our Visual 3D Scanning service uses advanced image-based technology to capture high-resolution, detailed visual representations of your parts. Benefit from accurate, detailed scans that facilitate precise modeling and analysis, ensuring high-quality results in your projects.

03

Scan-to-Editable CAD Development

Seamless Conversion from Scans to Editable Models. Our Scan-to-Editable CAD Generation service converts 3D scan data into fully editable CAD models, facilitating easy modifications and improvements. Simplify your design process with editable CAD models that allow for quick and efficient modifications, enhancing your product development cycle.

04

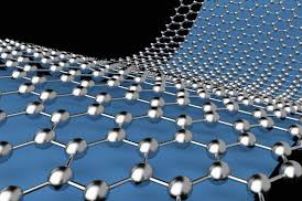

Material Identification (XRF-Based)

Accurate Material Analysis for Informed Decisions. Our Material Identification service uses XRF (X-ray Fluorescence) technology to accurately identify and analyze the composition of materials in your composite parts. Make informed decisions about material selection and usage with precise composition analysis, ensuring optimal performance and quality of your composite parts.

Our Team of Experts

Our expertise of domain allows us to deliver comprehensive solutions that address clients’ product design, computational analysis, simulation and manufacturing needs

Mechanical Engineers

Material Engineers

Manufacturing Engineers

Quality Assurance Engineers

Supply Chain Specialists

Regulatory Compliance Experts