Features

01

Expertise of Multiple Materials & Process Technology

02

Quality Assurance and Precision Manufacturing

03

Customization and Flexibility of Parts & Processes

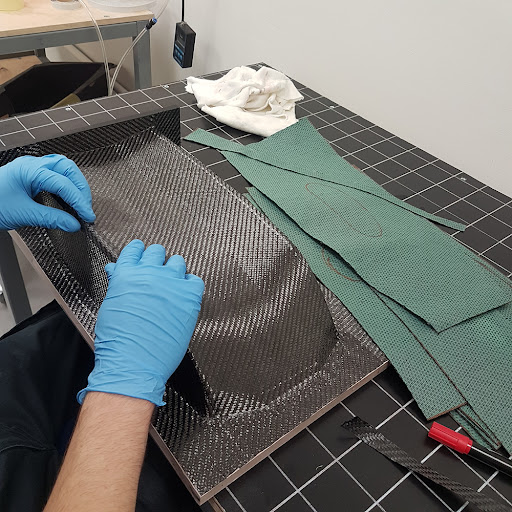

Fiber-Reinforced Composite Manufacturing

Explore the range of services.

01

Out-of-Autoclave Pre-preg Part Fabrication

High-Quality Composite Fabrication without Autoclaves. Our OOA Pre-preg Fabrication Process produces high-quality composite parts without the need for autoclave curing. Achieve exceptional strength and consistency in your composite parts with cost-effective and versatile fabrication methods.

02

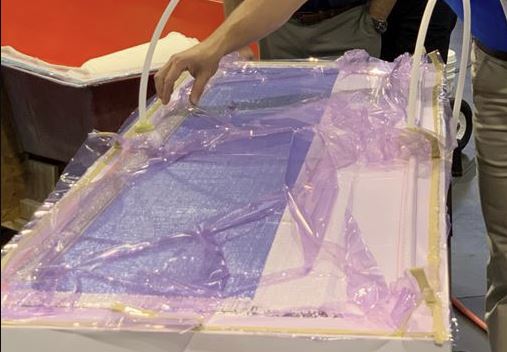

Vacuum Resin Infusion Part Fabrication

Precise and Strong Composite Parts. Our Vacuum Resin Infusion Process ensures precise control over resin distribution, resulting in strong, lightweight composite parts. Benefit from enhanced mechanical properties, reduced void content, and superior surface finish for your composite parts.

03

Wet Layup Part Fabrication

Flexible and Cost-Effective Composite Fabrication. Our Wet Layup Process offers a flexible and cost-effective method for fabricating composite parts with high-quality finishes. Quickly produce custom composite parts with excellent surface quality and reduced production costs.

04

Controlled Oven Curing of Parts

Consistent and Controlled Curing for Optimal Performance. Our Oven Curing service provides consistent and controlled curing of composite parts for optimal mechanical properties. Ensure uniform curing and enhanced performance of your composite parts, improving their durability and strength.

05

Spray Print & Finishing Works

Enhanced Aesthetics and Surface Quality. Our Spray Print & Finishing Works provide high-quality surface finishes and aesthetic enhancements for your composite parts. Improve the appearance and surface quality of your composite parts, ensuring they meet the highest standards of aesthetics and functionality.

Our Team of Experts

Our expertise of domain allows us to deliver comprehensive solutions that address clients’ product design, computational analysis, simulation and manufacturing needs

Mechanical Engineers

Material Engineers

Manufacturing Engineers

Quality Assurance Engineers

Supply Chain Specialists

Regulatory Compliance Experts